CRN Registration for Boilers and Pressure Vessels

Boilers & Pressure Vessels CRN Registration with TRG

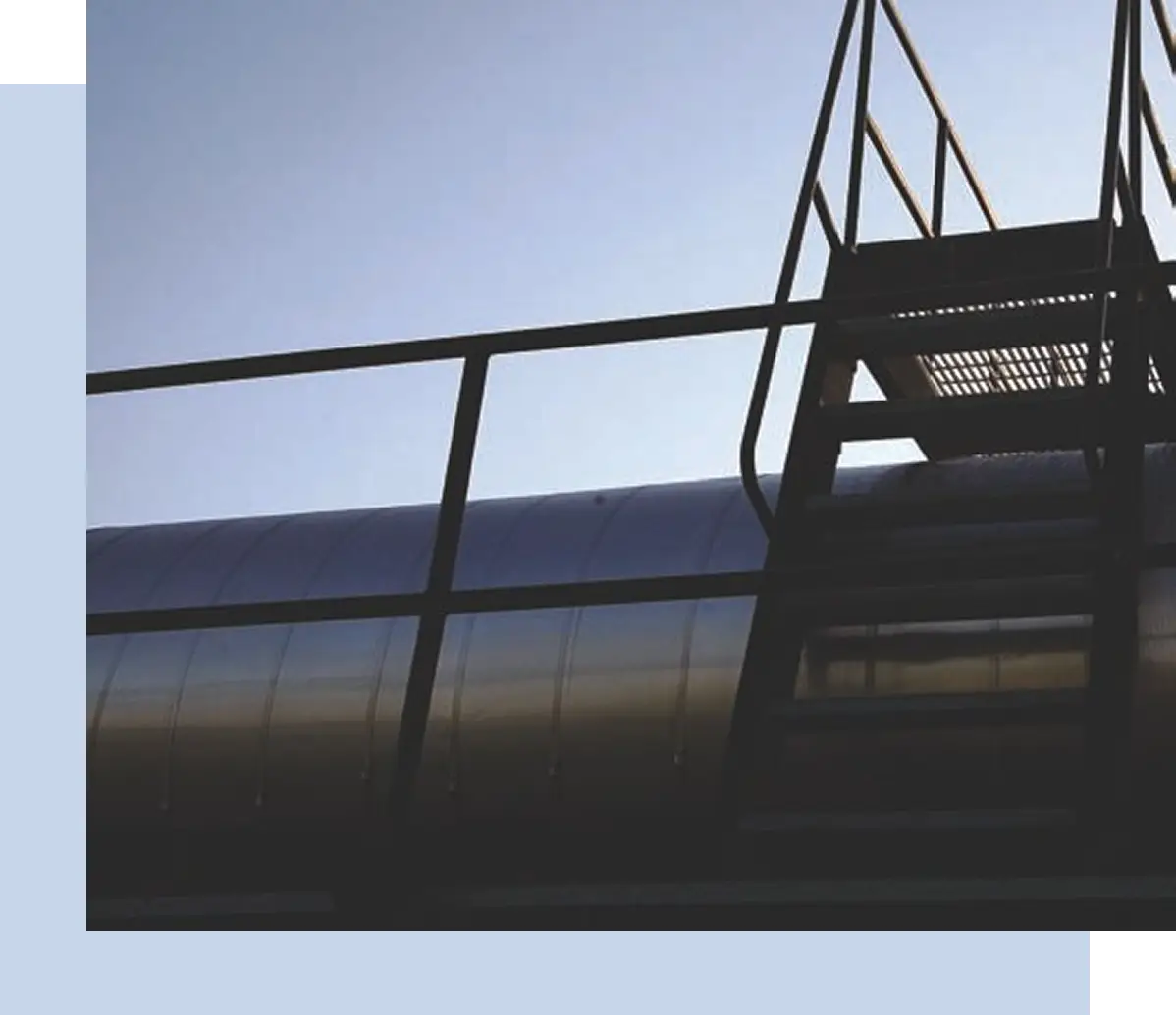

Boilers and pressure vessels operating above 15 psi (1 bar) require a CRN before they can be legally used in Canada. For this, you need to meet stringent ASME, CSA, and other provincial safety standards.

Titan Research Group has been helping engineers and manufacturers get approvals for over 20 years. Our experienced team handles every step of the process, including code calculations, proof testing, and more.

We understand that regulatory delays are costly. That is why we create a well-planned application that speeds up approval and avoids costly rejections. TRG makes sure submissions match jurisdictional rules, reducing back-and-forth with regulators.

Why You Need CRN for Your Boilers & Pressure Vessels

CRN certification confirms that a boiler or pressure vessel meets ASME Boiler and Pressure Vessel Code (BPVC) and CSA B51 standards.

These rules exist to prevent failures and protect workers from hazardous incidents. They also maintain system integrity in oil and gas, manufacturing, and power generation industries.

In Canada, there are various regulatory bodies operating in different provinces and territories.

As for example, TSSA regulates safety standards in Ontario, ABSA in Alberta, and TSBC in British Columbia. You need to register your boilers and pressure vessels in each jurisdiction where you want to use them.

Boilers & Pressure Vessels CRN Services We Provide

The boilers and pressure vessel CRN application process is not easy. Even minor mistakes can lead to rejection. Expert help during this critical period can save you time and money.

We provide various boiler and pressure vessel CRN registration services to simplify the entire process. Our services include:

- Code calculations

- Proof testing

- Jurisdictional compliance management

- Application documentation

- Follow-up support

- CRN renewal

- CRN training

Partner with TRG for Boilers & Pressure Vessels CRN Help

Want to renew your CRN or receive a CRN for new equipment? Titan Research Group is here to assist you throughout the entire CRN registration process. Make your boilers and pressure vessels reach the market on time.

Call us today at:

TOLL FREE +1 800 820 0092

GERMANY TOLL FREE +0800 181 0229

INTERNATIONAL +011 49 800 181 0229