Hydrostatic Testing Services in Toronto

Asme Hydrostatic Test Requirements

Our ASME hydrostatic test services use ISO 17025 accredited, ISTA certified, ANAB accredited, CSA approved laboratories. We are no strangers to highly customized as well as routine testing and test system development based on decades of engineering experience.

We are no ordinary test laboratory service because we strive to work with our clients’ to maximize the desired test output cost effectively, and in a timely manner.

Pressure Testing

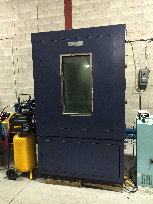

Right to left: High temp. steam, large safety chamber, high temp. pressure chamber

Asme Hydrostatic Test Requirements – Titan Research Group’s hydrostatic pressure testing services in Toronto utilizes state-of-the-art precision servo hydraulic pressure generators, which when compared to standard air-to-fluid pressure boosters, eliminates pressure fluctuation, and produces linear ramp rates.

Our hydro performance test lab features test equipment can utilize pressure transducers that are NIST traceable with ISO 17025 calibration certificates. The following ASME B31.3 pressure testing solutions are provided available:

- Pressure burst, leak and proof testing to CSA, ASTM, AWWA, ISO, and ASME standards

- TSSA witnessed proof testing service

- Advanced high pressure impulse cycle testing between 50 and 100,000 psi at rates up to 20 Hz. High tolerance trapezoid, square and sine waveforms can be controlled in very tight tolerance. Automatic sample failure detection.

- Combined pressure, load and temperature testing to apply mechanical load and extreme temperature conditions in a load range up to 110,000 lb from -70 to 600ºC

- Test mediums: water, steam, oil, calibration fluids, nitrogen & air

- Test pressure up to 100,000 psi

Structural and mechanical testing

- Cyclic and dynamic loading

- Load capacity up to 110,000 lb

- Servo-hydraulic test rigs

Pressure-Temperature curves for process instrumentation

Establishing reliable temperature de-rating curves for products not covered by published North American standards is becoming an industry norm and expectation. Not only is it prudent to provide de-rating guidelines, but it is essential to the safety of instrumentation operation to understand the pressure-temperature behaviour of the product under various conditions such as: inlet temperature, working fluid type, ambient temperature, and pressure.

Canadian Registration Number Pressure Testing

When applying for a Canadian Registration Number (CRN) the CSA B51 referenced code, or a particular Canadian review engineer at any one of the review authorities, may require witnessed pressure testing to ASME code, or other accepted code.

Package Testing

- ISTA standard package testing

- Shipping container testing up to 8’x5′

- mechanical and environmental simulation