Hydrostatic Testing Services

ASME Hydrostatic Test Requirements

Our ASME hydrostatic test services use ISO 17025 accredited, ISTA certified, ANAB accredited, CSA approved laboratories. We are no strangers to highly customized as well as routine testing and test system development based on decades of engineering experience.

We are no ordinary test laboratory service because we strive to work with our clients to maximize the desired test output cost-effectively, and in a timely manner.

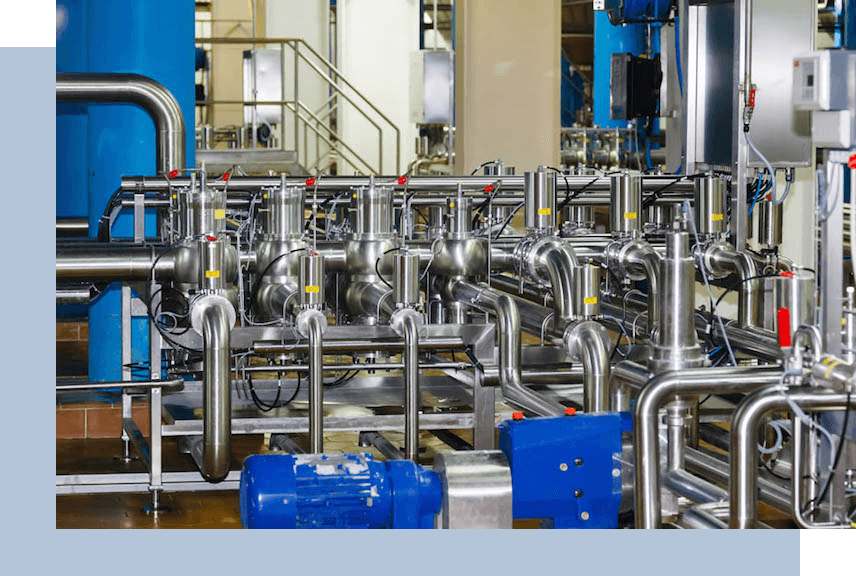

Pressure Testing

Right to left: High temp. steam, large safety chamber, high temp. pressure chamber

ASME Hydrostatic Test Requirements – Titan Research Group’s hydrostatic pressure testing services utilizes state-of-the-art precision servo hydraulic pressure generators, which when compared to standard air-to-fluid pressure boosters, eliminates pressure fluctuation and produces linear ramp rates.

Our hydro performance test lab features test equipment that can utilize pressure transducers that are NIST traceable with ISO 17025 calibration certificates. The following ASME B31.3 pressure testing solutions are provided:

- Pressure burst, leak and proof testing to CSA, ASTM, AWWA, ISO, and ASME standards

- TSSA witnessed proof testing service

- Advanced high pressure impulse cycle testing between 50 and 100,000 psi at rates up to 20 Hz. High tolerance trapezoid, square and sine waveforms can be controlled in very tight tolerance. Automatic sample failure detection.

- Combined pressure, load and temperature testing to apply mechanical load and extreme temperature conditions in a load range up to 110,000 lb from -70 to 600ºC

- Test mediums: water, steam, oil, calibration fluids, nitrogen & air

- Test pressure up to 100,000 psi

Industry Applications of Hydrostatic Testing

The Importance of Pressure Testing

Pressure testing is a critical step in verifying the integrity and safety of piping systems and pressure vessels. Tests are conducted at pressures exceeding the expected operating levels to confirm that the system can withstand normal service conditions without failure.

Equipped with advanced technology and extensive experience, Titan Research Group provides comprehensive pressure testing services for both liquid and gas applications. Our team can conduct tests at pressures up to 100,000 psi, ensuring all systems meet regulatory standards and are safe for commissioning and continued operation.

Structural and Mechanical Testing

✔ Cyclic and dynamic loading

✔ Load capacity up to 110,000 lb

✔ Servo-hydraulic test rigs

Pressure Testing Equipment For Pipes

Pressure Testing Equipment For Pipes is a test that is carried out at any under-construction site after the installation of the pipes before we put them into use. This is done to evaluate the certain limits of pipelines in terms of reliability, maximum capacity, leaks, joint fittings, and pressure. Without testing the installed pipelines, one cannot ensure if pipes meet the standard installation requirements. While the non-technical basic purpose of developing the system for pipelines is to ensure the safety of labor working on the construction site and outline the safety practices that must be carried out while testing pipes.

The main responsibility of Pressure Testing Equipment for Pipes lies with two personnel, the plumbing foreman and the project engineer. They perform the hydrostatic test to find out leakages or damages in the pipelines. The information received from the test helps construction personnel to maintain the safety standards and keep the pipelines in good working condition. This information is documented and signed by the assigned personnel.

The system uses two methods: Hydrostatic Pressure Testing Equipment For Pipes and Pneumatic Pressure. These test methods use the quick couplings and air compressors as the testing equipment.

Safety Protocols and Risk Management

Safety is critical during hydrostatic testing because pressurised systems can be hazardous if not managed correctly. Before testing begins, a thorough risk assessment is performed to identify potential hazards. All personnel follow strict personal protective equipment (PPE) requirements and safe work procedures. Equipment is inspected for integrity, and fail-safe pressure relief systems are in place to prevent accidental over-pressurisation.

Test plans include emergency shutoff procedures, monitoring protocols, and contingency steps for unexpected failures. By following these strict safety measures, hydrostatic testing not only verifies system integrity but also protects personnel, property, and the surrounding environment.

Pressure-Temperature Curves for Process Instrumentation

Establishing reliable temperature de-rating curves for products not covered by published North American standards is becoming an industry norm and expectation. Not only is it prudent to provide de-rating guidelines, but it is essential to the safety of instrumentation operation to understand the pressure-temperature behaviour of the product under various conditions such as: inlet temperature, working fluid type, ambient temperature, and pressure.

Canadian Registration Number Pressure Testing

When applying for a Canadian Registration Number (CRN), the CSA B51 referenced code, or a particular Canadian review engineer at any one of the review authorities, may require witnessed pressure testing to ASME code, or other accepted code.

Advanced Testing Techniques and Innovations

Modern hydrostatic testing has evolved beyond basic pressure checks. Today, advanced techniques allow for precise, repeatable, and data-driven testing. Digital pressure monitoring systems provide real-time feedback on pressure changes, while automated data logging creates detailed test reports that support regulatory audits. High-frequency impulse testing simulates rapid pressure fluctuations to uncover potential failure points before equipment is put into service.

Moreover, some labs integrate non-destructive evaluation (NDE) methods alongside hydrostatic testing to detect micro-cracks or weak welds without damaging equipment. These innovations guarantee more accurate results, minimise retesting, and reduce overall downtime for clients.

Package Testing

✔ ISTA standard package testing

✔ Shipping container testing up to 8’x5′

✔ Mechanical and environmental simulation

CLIENTS WE’VE HELPED WITH OUR TESTING SERVICES

Contact Our Experts

Call us today at:

TOLL FREE +1 800 820 0092

GERMANY TOLL FREE +0800 181 0229

INTERNATIONAL +011 49 800 181 0229

FAQs About Hydrostatic Pressure Testing

- ASME pressure vessel hydrostatic test – for ASME-certified vessels.

- Pneumatic tests – using air or gas instead of water.

- Hydrostatic tests are preferred for safety because water is incompressible.