How to Get a CRN in Canada: Step-by-Step Guide

August 18, 2025

CRN for Industries: What Every Business Needs to Know in 2025

October 23, 2025When products are designed to handle pressurized fluids or gases, safety and compliance are never optional. Burst testing provides the data manufacturers need to confirm how much pressure a component can withstand before it fails. At Titan Research Group, we specialize in testing services that give engineering teams and regulators confidence in the equipment they use and approve.

What Burst Testing Means

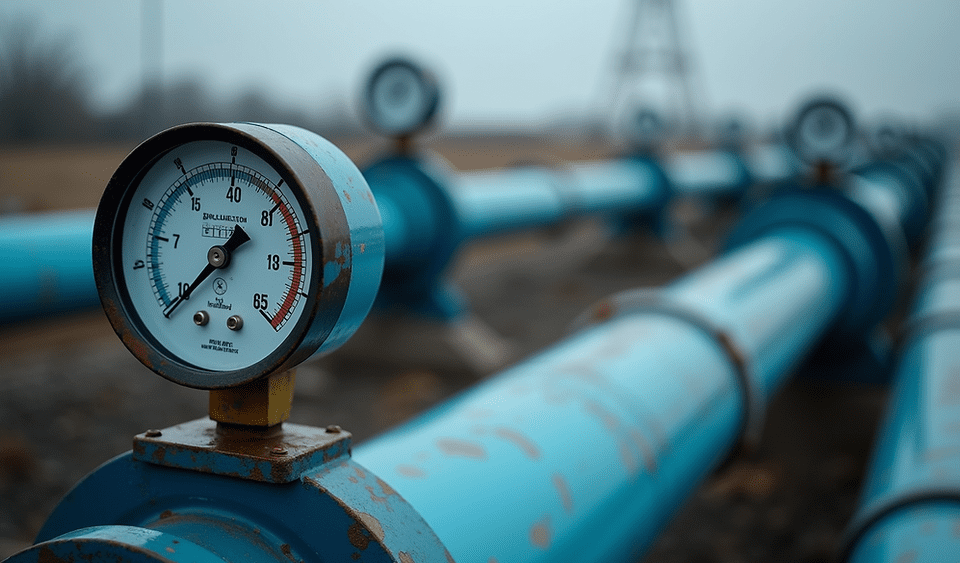

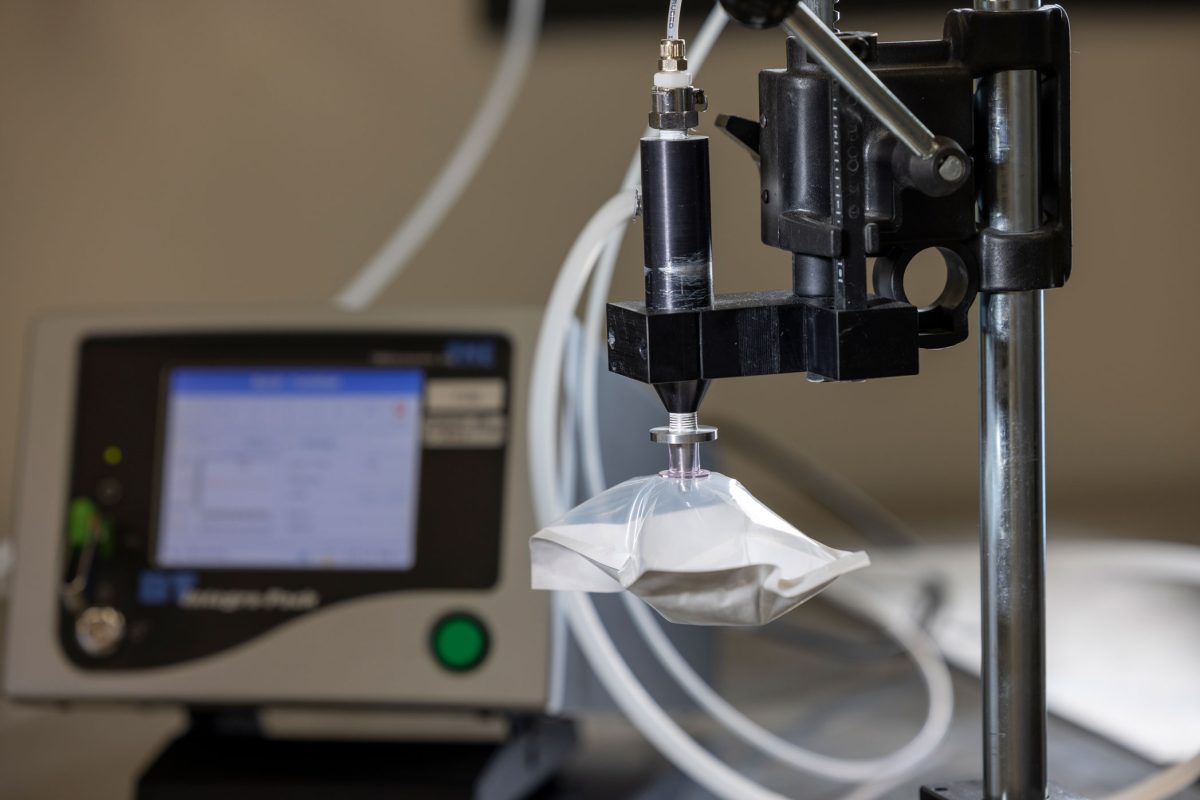

Burst testing is a destructive pressure test used on vessels, fittings, and piping systems. The goal is to find the exact pressure point where the product fails. Testing is normally done with water through hydrostatic methods, but can also use gas in certain applications. The recorded burst pressure is then compared against design expectations and code requirements.

This type of testing provides information that calculations alone cannot reveal. Weak welds, material inconsistencies, or hidden manufacturing flaws become obvious when a product is stressed until failure.

Why Burst Testing Is Required

Canadian regulations often require manufacturers to obtain a Canadian Registration Number (CRN) for their pressure equipment. In many cases, part of this process involves burst testing to demonstrate that the equipment meets safety margins defined by codes such as ASME and CSA.

Without this verification, equipment risks rejection by regulators or, worse, unsafe use in the field. Working with an experienced Burst Testing company ensures testing is carried out correctly, witnessed when required, and properly documented for regulatory submissions.

How Burst Testing Benefits Manufacturers

Burst testing offers several important benefits:

- Proof of safety margins: Confirms that a design can handle far more than its intended operating pressure.

- Design improvement: Identifies the weak points in a product, leading to stronger and safer redesigns.

- Regulatory compliance: Helps satisfy CRN application requirements, reducing delays and rework.

- Risk reduction: Prevents costly failures in service by identifying vulnerabilities during testing instead of during operation.

When data from burst testing is combined with proof testing and inspections, manufacturers gain a complete picture of how their equipment will perform in real conditions.

The Testing Process at Titan Research Group

At Titan Research Group, we follow a structured process designed to ensure accuracy, safety, and compliance:

Preparation – Reviewing product drawings, materials, and specifications to determine the appropriate setup.

Execution – Applying pressure gradually until the product bursts, while carefully monitoring and recording the test.

Analysis – Evaluating results against code requirements and design expectations.

Reporting – Delivering detailed documentation that can be used in regulatory submissions or internal design reviews.

This approach allows manufacturers to meet compliance requirements while also learning more about their product’s performance under extreme conditions.

When Burst Testing Is Important

Not all equipment needs burst testing, but it becomes essential in applications where failure could lead to serious consequences. Examples include:

- High-pressure piping and fittings in oil, gas, and petrochemical facilities

- Pressure vessels used in chemical, pharmaceutical, and food industries

- Boilers and steam systems in power generation

- Components in water treatment and agricultural systems

In these industries, failure often means more than just downtime. It can result in safety hazards, environmental issues, or damage to reputation. That’s why partnering with a qualified burst testing company is such an important decision.

Why Work With Titan Research Group

With over 20 years of experience, we understand both the technical and regulatory sides of burst testing. We help clients navigate Canadian requirements, prepare for CRN applications, and complete testing in a way that regulators accept. Beyond the compliance aspect, our testing services give manufacturers practical insights into how their products perform under maximum stress.

Final Thoughts

Burst testing goes beyond theory to prove how equipment behaves under real-world conditions. It demonstrates compliance, highlights weak points, and ensures products are safe for use in demanding industries.

If your organization needs a trusted burst testing company to validate products and support CRN submissions, Titan Research Group can help. Contact us today, and our team will provide accurate testing, clear reporting, and guidance through the regulatory process.